sustainability

Take responsibility. Shape the future.

At STADISEAT, sustainability is not a promise, but an integral part of every single seat.

We equip stadiums with high-quality, durable, and fully recyclable stadium seats – made from 100% recycled material and with 79% lower CO₂ emissions compared to conventional production.

For fans. For clubs. For the environment.

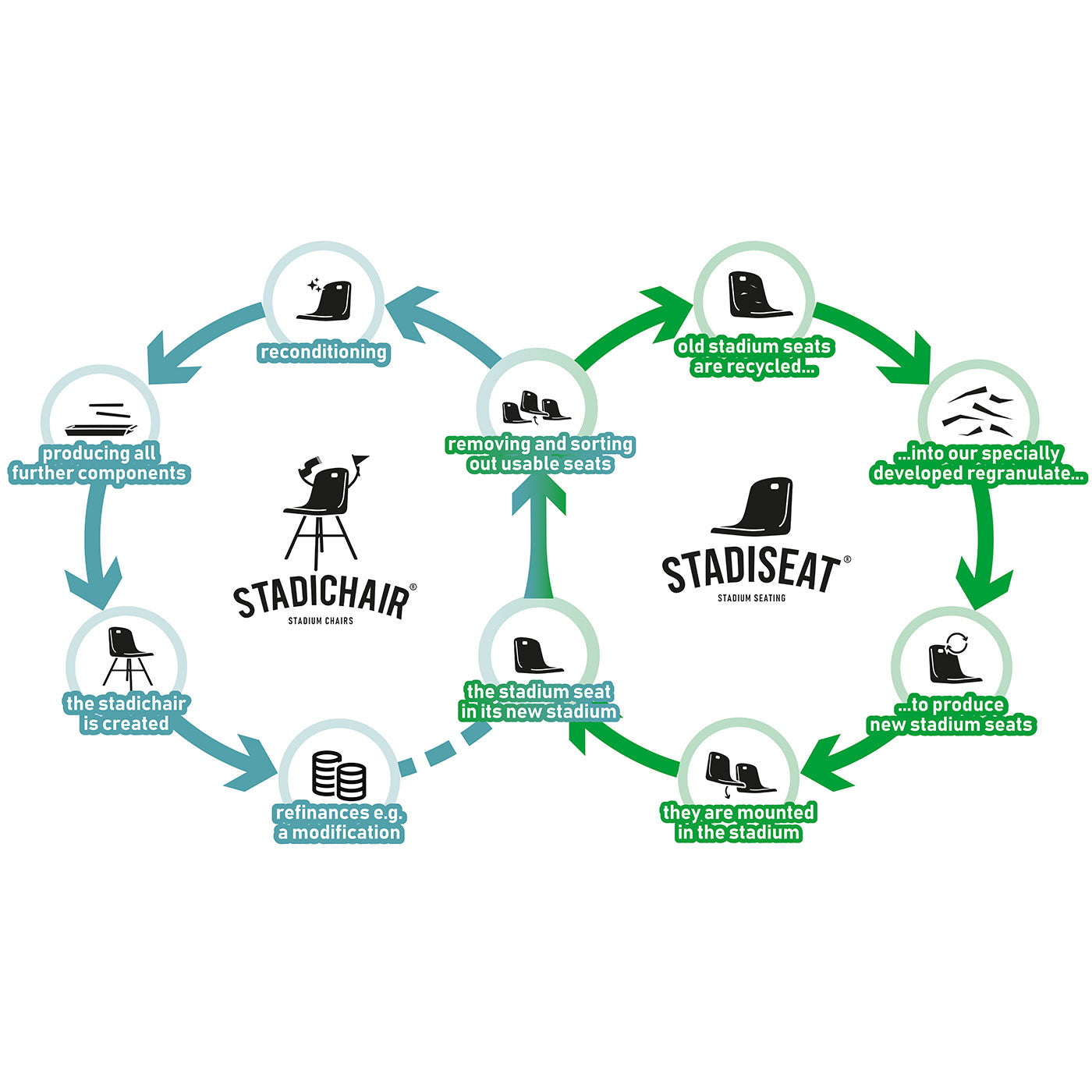

Cradle to Cradle: The closed material cycle

At STADISEAT, sustainability isn't just on paper—it's embedded in every single stadium seat we produce. Our goal: to equip stadiums with high-quality, durable, and recyclable stadium seats. For fans. For clubs. For the environment.

Our sustainability promise

STADISEAT stands for a true circular economy.

1️⃣ Dismantling & sorting

Our cycle begins with the replacement of old stadium seats: The old seats are systematically dismantled and sorted. Seats that are still intact are carefully refurbished and prepared for new use. Defective seats are recycled and serve as the basis for new raw material.

2️⃣ Recycling & raw material extraction

The unusable seats are completely disassembled and separated into their pure components. This creates our specially developed regranulate, which is then recycled as a high-quality raw material into the production of new STADISEAT stadium seats—without any material loss.

3️⃣ Production & Assembly

We use the regranulate to manufacture new stadium seats in Germany using a resource-saving injection molding process – with CO₂ savings of up to 79% compared to conventional production.

The finished seats are assembled directly in the stadiums.

4️⃣ Secondary utilization & refinancing

Usable, removed seats are given a second life by STADICHAIR. The proceeds from these sales help the clubs finance their modernization projects. After use, all seats are returned to the cycle—a true circular economy with zero waste.

Our sustainability advantages at a glance

✅ 100% recyclable

✅ Manufactured according to the cradle-to-cradle principle

✅ Partnership-based recycling system with return of old seats

✅ Up to 79% CO₂ savings compared to conventional production

✅ Regional production in Germany

✅ Economic benefits for clubs through recycling

✅ Resource-saving production using injection molding

✅ Transparent, verifiable and audited processes

short distances & high standards

Made in Germany

Our stadium seats are manufactured entirely in Germany. This ensures short transport routes, maximum quality assurance, and fair working conditions throughout the entire value chain.

Regional production

founder

Sustainability begins with production routes. Short distances mean fewer emissions — right from the start.

Jonas Braamt

By manufacturing in Germany, we can process our materials in a pure manner. This results in stadium seats that are fully recycled and returned to the cycle at the end of their useful life.

100% recyclable